When our engineers analyze flight data from crashed units, we often find that inadequate sensor specifications caused the accident. Losing a heavy sprayer drone due to poor detection heavy sprayer drone 1 is an expensive nightmare you must avoid.

To ensure safety, specify a 360-degree omnidirectional radar system combined with binocular vision sensors for redundancy. Require a minimum detection range of 50 meters, the ability to identify 1-centimeter thin wires, and IP67-rated modules that resist corrosion from pesticide exposure during daily wash-downs.

Selecting the right sensors determines whether your drone finishes the job or ends up in the repair shop, so let’s examine the exact technical standards you need.

Is millimeter-wave radar or binocular vision better for my agricultural drone safety?

In our factory testing facility, we simulate heavy fog and blinding sunlight to see how different sensors react. Relying on a single detection method often leads to blind spots during critical operations.

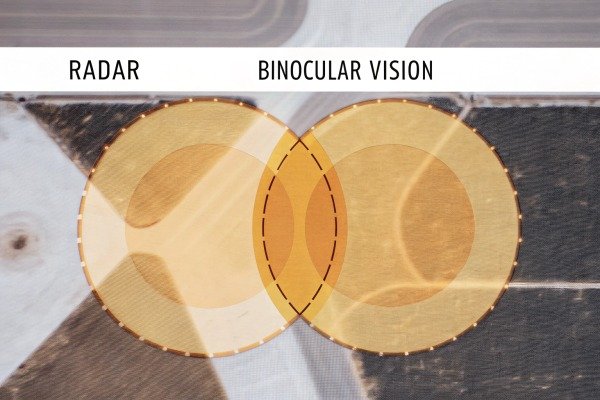

For maximum safety, do not choose between them; require sensor fusion technology that combines both. Millimeter-wave radar ensures operation in dust and night conditions, while binocular vision provides high-resolution 3D mapping for identifying complex structures like fences, guaranteeing comprehensive protection in all environments.

When we discuss sensor technology with our clients in the United States and Europe, there is often a misconception that one "best" sensor exists. In reality, agricultural agricultural drones 2 environments are too diverse for a single sensor type to handle alone. We strongly advise procurement managers to look for "Sensor Fusion." This is not just a buzzword; it is a critical architecture where the flight computer processes data from multiple sources simultaneously.

The Strengths and Weaknesses of Radar

Millimeter-wave radar (often 77GHz or 24GHz) is the backbone of heavy-duty agricultural drones. Millimeter-wave radar 3 Its primary advantage is indifference to light and particulate matter. When your operators are spraying at dawn, dusk avoid harming pollinators 4, or even at night to avoid harming pollinators, cameras become unreliable. Furthermore, agricultural fields are dusty, and spray nozzles create a mist of chemical droplets. Visual cameras can interpret this mist as an obstacle or get "blinded." Radar penetrates this interference effortlessly. However, radar struggles with resolution. It might detect "something" is there, but it has trouble distinguishing a steel pole from a dense cornstalk, or a thin wire from empty space.

The Role of Binocular Vision

Binocular vision works like human eyes. It uses two cameras to calculate depth and create a 3D point cloud 5 3D point cloud of the environment. This is superior for resolution. It can clearly define the edges of a barn, a tractor, or a tree canopy. However, just like human eyes, it fails in low light or direct glare. If the drone turns directly into the sun, the cameras can wash out.

Why You Need Both

By specifying a system that integrates both, you get the best of both worlds. The radar provides long-range detection (up to 50-60 meters) and night capability. The vision system provides short-range precision and obstacle classification. Below is a comparison to help you verify specs with suppliers:

| Feature | Millimeter-Wave Radar | Binocular Vision | Sensor Fusion (Required) |

|---|---|---|---|

| Primary Detection Mechanism | Radio waves (echo) | Optical image processing | Combined Data Stream |

| Performance in Darkness | Excellent (Unaffected) | Poor (Blind) | Excellent |

| Performance in Dust/Mist | Excellent (Penetrates) | Poor (Obstructed) | Good (Redundant backup) |

| Object Resolution | Low (Blob detection) | High (Shape/Edge detection) | High |

| Wire Detection | Weak | Strong | Strong |

| Maintenance Need | Low | High (Lens cleaning) | Moderate |

When you send an inquiry to a supplier, explicitly ask: "Does the obstacle avoidance system rely solely on vision, or does it utilize a fusion of spherical radar and vision sensors?" This simple question can save you from purchasing outdated technology.

How do I ensure the obstacle avoidance system handles terrain following on uneven slopes?

We frequently calibrate flight controllers for clients operating in hilly regions, where ground levels shift rapidly. A drone that cannot adjust altitude instantly will drive its spray nozzles directly into the crop canopy.

You must specify terrain-following radar with a refresh rate of at least 50Hz and Real-Time Kinematic (RTK) integration. This combination ensures the drone detects ground changes instantly and maintains a precise height above crops, even on slopes up to 45 degrees, preventing crashes on uneven ground.

Terrain following is technically distinct from horizontal obstacle avoidance, but they utilize the same sensor ecosystem. For flat cornfields in the Midwest, standard GPS altitude hold is often sufficient. However, for vineyards, tea plantations, or terrace farming, the ground is a moving target. If your drone flies at 5 meters per second and the ground rises sharply, a delay of even half a second in sensor processing can cause a collision.

The Mechanics of Terrain Radar

Standard obstacle avoidance looks forward. Terrain following looks down. You need to ensure the specific drone model has a dedicated downward-facing radar module or a phased-array radar that angles downward. This radar constantly pings the ground to measure "Relative Altitude" (height above the crop) rather than "Absolute Altitude" (height above sea level).

The Critical Role of RTK

RTK (Real-Time Kinematic) technology corrects GPS errors to centimeter-level accuracy. Real-Time Kinematic 6 While RTK is primarily for position (X, Y axis), it stabilizes the Z-axis (altitude) significantly. When we design our flight algorithms, we fuse the radar altitude data with RTK stability. This prevents the drone from drifting up and down due to barometric pressure changes, which can happen when weather shifts rapidly on a farm.

Handling Crop Canopy vs. Hard Ground

A common issue we see with cheaper sensors is "False Floor" detection. This happens when the radar thinks the top of a tall crop (like sugarcane or mature corn) is the ground. If the drone tries to land or fly low, it might stop 2 meters too high, or worse, the sensor might punch through a gap in the crop, think the ground is lower, and drop the drone into the plants. High-quality millimeter-wave radar can be tuned with High-quality millimeter-wave radar 7 "Crop Penetration Filtering" to distinguish between the soft return of a canopy and the hard return of the soil.

When evaluating a spec sheet, look for these specific terrain parameters:

| Parameter | Recommended Specification | Why it Matters |

|---|---|---|

| Terrain Radar Range | 0.5m to 100m | Needs to see the ground from high transit altitudes. |

| Max Slope Angle | ≥ 30 degrees (ideally 45°) | Ensures the drone doesn't stall on steep hills. |

| Response Latency | < 20 milliseconds | Vital for fast flying over bumpy terrain. |

| Precision | ± 0.1 meters | Guarantees consistent spray application. |

We also recommend asking suppliers if their system allows for "Terrain Mapping." This is a feature where the drone flies a survey flight first to map the slope, saving the 3D terrain data. On subsequent spray runs, the drone anticipates the slope changes rather than reacting to them, leading to much smoother flight and better battery efficiency.

What specifications guarantee the drone can detect thin wires and tree branches effectively?

Our repair team often receives units entangled in guy wires, which are practically invisible to older sensors. Detecting a solid wall is easy, but identifying a 5-millimeter cable against a bright sky is an immense engineering challenge.

Require active binocular vision systems capable of detecting obstacles as thin as 1 centimeter from a distance of at least 15 meters. Additionally, ensure the system includes “Wire Enhancement” algorithms that specifically scan for linear patterns, as standard radar often fails to register thin, non-conductive, or negative-space objects.

Thin wires—power lines, telephone cables, and guy wires supporting utility poles—are the number one enemy of agricultural drones. In many rural areas, these wires are unmapped and can appear anywhere across a field. Standard radar works by receiving a signal bounce-back (echo). A round, thin wire scatters radar waves rather than reflecting them back, making the wire invisible to the radar until it is too late.

The "15-Meter Rule"

Why do we specify detection at 15 meters? It is about physics and inertia. A fully loaded agricultural drone (like our 40-liter models) carries significant momentum. If it is flying at a standard spray speed of 7 meters per second, it needs distance to stop.

- Reaction time: The sensor sees the wire (0.1s).

- Processing time: The computer confirms it is an obstacle (0.1s).

- Braking time: The motors reverse thrust to stop the heavy mass (1.5s – 2.0s).

If the drone only detects the wire at 5 meters, physics dictates a crash. 15 meters provides a safety buffer.

Vision Processing Algorithms

Hardware is only half the battle. The software must be smart. We utilize machine learning models trained on thousands machine learning models 8 of images of power lines and bare tree branches. These algorithms look for specific linear contrast changes in the video feed. When purchasing, ask if the drone features "Semantic Semantic Segmentation 9 Semantic Segmentation 10 Segmentation" or specific "Wire Detection Mode."

- Daytime: Vision sensors excel here. They see the black line against the blue sky or green field.

- Nighttime: This is the danger zone. Vision sensors are blind. Unless the drone has FPV spotlamps (powerful LED lights) that illuminate the path ahead, wire detection at night is nearly impossible. If you plan to spray at night, you must map the obstacles during the day first.

Environmental Factors Reducing Detection

Be aware that certain conditions degrade detection capabilities:

- Backlighting: Flying directly toward the sun hides wires in the glare.

- Complex Backgrounds: A grey wire against a grey cloudy sky or a brown branch against a brown forest background is hard to see.

Technical Checklist for Wire Detection

When vetting a supplier, use this checklist to verify their wire detection claims:

| Component | Requirement | Note |

|---|---|---|

| Camera Resolution | Minimum 1080p equivalent | Lower resolution blurs thin lines. |

| Min. Detectable Diameter | ≤ 1 cm (0.4 inches) | Standard for guy wires. |

| Detection Distance | ≥ 15 meters (50 feet) | Critical for braking distance. |

| Night Lighting | Integrated High-Lumen Spotlights | Essential for night vision wire detection. |

| Algorithm Type | Edge Detection / Linear Analysis | Specific software for wires. |

Should I look for autonomous bypassing capabilities or simple braking when obstacles are detected?

We often debate this logic with our software developers: should the drone be smart enough to go around, or safe enough to just stop? In complex farm environments, overly aggressive autonomy can sometimes introduce new, unpredictable risks.

For agricultural operations, prioritize “Hover and Alert” (braking) over autonomous bypassing, especially near power lines. While bypassing is useful in open fields, the risk of a drone vertically bypassing into overhead wires is high; simple braking allows the pilot to visually assess the situation and manually navigate safely.

This is a controversial topic in the drone industry. Marketing materials often boast about "Smart Bypass" or "3D Obstacle Navigation," making it sound like the drone can weave through a forest like a bird. In reality, for a heavy agricultural drone carrying 40kg of liquid, predictability is safer than autonomy.

The Risks of Autonomous Bypassing

There are two types of bypassing:

- Horizontal Bypass: The drone steers left or right to go around the tree.

- Risk: It might steer into a neighboring row of crops, a fence, or another tree that wasn't in the primary field of view.

- Vertical Bypass: The drone climbs up to fly over the obstacle.

- Risk: This is extremely dangerous in agriculture. Farmers often place obstacles (like pumps or sheds) near power lines. If a drone detects a shed and decides to "climb over" it automatically, it may fly directly into the high-voltage lines running above the shed.

Why "Braking" is often the Pro Choice

Professional operators usually prefer the drone to come to a hard stop (brake) and hover.

- Safety: It gives control back to the human. You can check the FPV camera, see what the obstacle is, and decide the safest path.

- Precision: If the drone bypasses automatically, it misses spraying the area around the obstacle. If it brakes, the pilot can carefully navigate around it, ensuring better crop coverage.

- Efficiency: Frequent bypassing creates an erratic flight path that consumes more battery than a straight line with a controlled stop.

When Bypassing Makes Sense

Bypassing is acceptable in "Open Field" modes where obstacles are simple, solitary trees in the middle of a massive field. In this specific case, the drone can slightly deviate and return to the path without risk.

Smart Modes to Look For

Instead of a simple "On/Off" switch, look for drones that offer selectable strategies based on the field type. A robust system should offer the following logic options:

| Strategy Name | Behavior | Recommended Scenario |

|---|---|---|

| Stop & Hover | Detects obstacle, brakes, waits for pilot input. | Complex fields, near power lines, tight spaces. |

| Horizontal Bypass | Detects obstacle, plans path around, rejoins route. | Single trees in large open fields. |

| Vertical Bypass | Detects obstacle, climbs over, descends. | NOT RECOMMENDED for most farms due to overhead wire risk. |

| Obstacle Marking | Brakes, allows pilot to mark obstacle on map, updates route. | First time flying a new field. |

From our manufacturing perspective, we always recommend customers configure their fleet to "Stop & Hover" by default. It is the fail-safe option. You should also check if the drone has "Sensor Occlusion Alerts." If mud covers the radar, the drone should refuse to take off or alert you, rather than flying blind. This self-diagnosis is a key requirement for long-term safety.

Conclusion

When purchasing agricultural drones, do not settle for generic "obstacle avoidance" claims. Demand specific capabilities: sensor fusion (radar + vision) for all-weather reliability, terrain following with RTK for slopes, 15-meter detection ranges for thin wires, and a configurable braking logic that prioritizes safety over fancy autonomous maneuvers. By specifying these detailed requirements, you ensure your investment remains in the air and productive, rather than grounded by preventable accidents.

Footnotes

1. Link to a leading manufacturer’s product page illustrates the specific type of equipment discussed. ↩︎

2. The FAO provides authoritative global context on the implementation of drones in agriculture. ↩︎

3. Texas Instruments is a leading manufacturer defining the technical standards for mmWave sensor technology. ↩︎

4. Official government guidelines regarding pesticide application safety and environmental protection. ↩︎

5. Educational reference defining the technical output of binocular vision systems. ↩︎

6. NovAtel provides the industry-standard technical definition for RTK GNSS correction methods. ↩︎

7. Product documentation from a leading sensor manufacturer detailing radar capabilities. ↩︎

8. Educational link to a research institution explaining the fundamentals of the algorithms mentioned. ↩︎

9. General background reference defining the computer vision technique used for wire detection. ↩︎

10. MathWorks provides a technical overview of the computer vision algorithms used for object classification. ↩︎